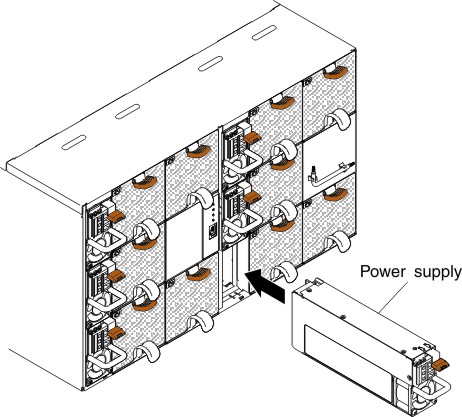

To install a hot-swap DC power supply, complete the following steps.

- Only trained service personnel other than Lenovo service technicians are authorized to install and remove the -48 volt DC power supply, and make the connections to and disconnections from the -48 volt DC power source. Lenovo service technicians are not certified or authorized to install or remove the -48 volt power cable. The customer is responsible for ensuring that only trained service personnel install or remove the -48 volt power cable.

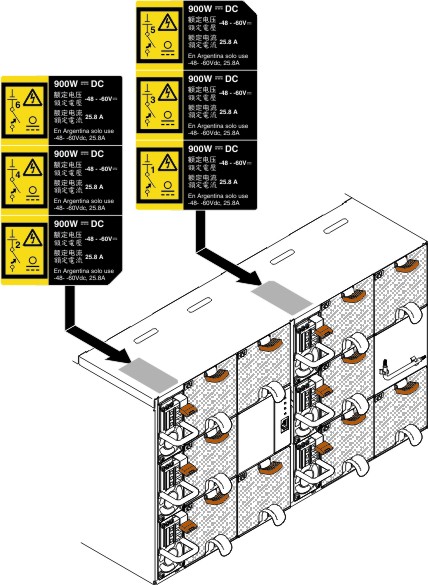

- Before you install a DC power supply in the server, you must remove all AC power supplies. Do not use both AC and DC power supplies in the same server. Install six DC power supplies or six AC power supplies, but not a combination.

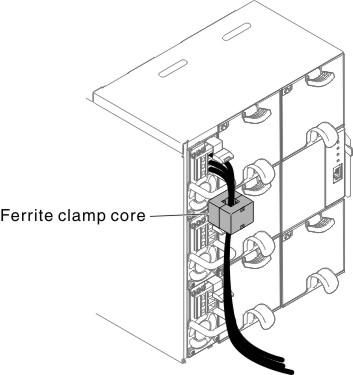

- If you need to order more ferrite clamp cores, the part number is 94Y8175.

Regulations

- It is the customer's responsibility to supply the necessary power

cable.To reduce the risk of electric shock or energy hazards:

- Use a circuit breaker that is rated at 70 amps.

- Use 4 mm2 (10 AWG) at 90° C copper wire.

- Torque the wiring-terminal screws to 0.50 ~ 0.60 newton-meters (4.43 ~ 5.31 inch-pounds).

- If the power source requires ring terminals, you must use a crimping tool to install the ring terminals to the power cord wires. The ring terminals must be UL approved and must accommodate the wire that is described in the above-mentioned note.

- To avoid radiated emission, you must attach a clamp core for each

of the 900 W DC power supply used.Figure 1. Ferrite clamp core

Statement 29

CAUTION: This equipment is designed to permit the connection of the earthed conductor of the DC supply circuit to the earthing conductor at the equipment.

This equipment is designed to permit the

connection of the earthed conductor of the DC supply circuit to the

earthing conductor at the equipment. If this connection is made, all

of the following conditions must be met:

- This equipment shall be connected directly to the DC supply system earthing electrode conductor or to a bonding jumper from an earthing terminal bar or bus to which the DC supply system earthing electrode conductor is connected.

- This equipment shall be located in the same immediate area (such as, adjacent cabinets) as any other equipment that has a connection between the earthed conductor of the same DC supply circuit and the earthing conductor, and also the point of earthing of the DC system. The DC system shall not be earthed elsewhere.

- The DC supply source shall be located within the same premises as this equipment.

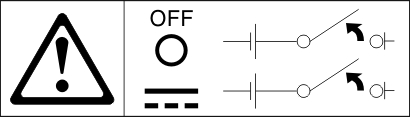

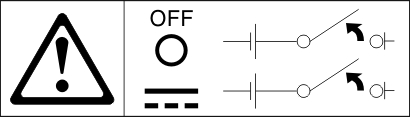

- Switching or disconnecting devices shall not be in the earthed circuit conductor between the DC source and the point of connection of the earthing electrode conductor.

Statement 31

DANGER

Electrical current from power,

telephone, and communication cables is hazardous.

To avoid a shock hazard:

- Do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration of this product during an electrical storm.

- Connect all power cords to a properly wired and grounded power source.

- Connect to properly wired power sources any equipment that will be attached to this product.

- When possible, use one hand only to connect or disconnect signal cables.

- Never turn on any equipment when there is evidence of fire, water, or structural damage.

- Disconnect the attached ac power cords, dc power sources, network connections, telecommunications systems, and serial cables before you open the device covers, unless you are instructed otherwise in the installation and configuration procedures.

- Connect and disconnect cables as described in the following table when you install, move, or open covers on this product or attached devices.

| To Connect: | To Disconnect: |

|---|---|

|

|

Statement 33

CAUTION:

This product does not provide

a power-control button. Turning off blades or removing power modules

and I/O modules does not turn off electrical current to the product.

The product also might have more than one power cord. To remove all

electrical current from the product, make sure that all power cords

are disconnected from the power source.

Statement 34

CAUTION:

To reduce the risk

of electric shock or energy hazards:

- This equipment must be installed by trained service personnel in a restricted-access location, as defined by the NEC and IEC 60950-1, First Edition, The Standard for Safety of Information Technology Equipment.

- Connect the equipment to a properly grounded safety extra low voltage (SELV) source. A SELV source is a secondary circuit that is designed so that normal and single fault conditions do not cause the voltages to exceed a safe level (60 V direct current).

- Incorporate a readily available approved and rated disconnect device in the field wiring.

- See the specifications in the product documentation for the required circuit-breaker rating for branch circuit overcurrent protection.

- Use copper wire conductors only. See the specifications in the product documentation for the required wire size.

- See the specifications in the product documentation for the required torque values for the wiring-terminal screws.