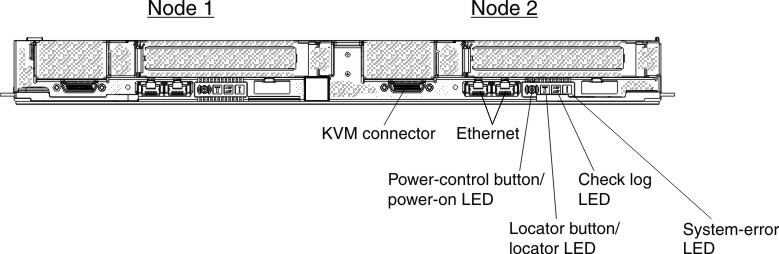

The following illustration shows the controls, LEDs, and connectors on the front of the NeXtScale nx360 M5 water-cooled technology tray Type 5467.

There are two separate nodes in a single tray. The following illustration identifies the buttons, connectors, and LEDs on the control panel.

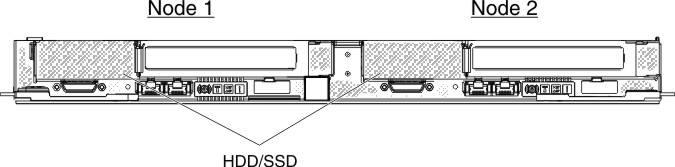

If you have the optional hard-disk drives(HDDs) or solid-state drives(SSDs) installed, the following illustration identifies their locations.

- Power button/LED

- When the water-cooled technology tray is connected to power through the Lenovo NeXtScale n1200 Enclosure

Type 5468,

press this button to turn on or turn off the water-cooled technology tray. This button is also the power LED. This green LED indicates the power status of the water-cooled technology tray:

- Flashing rapidly: The LED flashes rapidly for the following

reasons:

- The water-cooled technology tray has been installed in a chassis. When you install the water-cooled technology tray, the LED flashes rapidly for up to 90 seconds while the integrated management module (IMM2.1) in the water-cooled technology tray is initializing.

- The Lenovo NeXtScale n1200 Enclosure Type 5468 does not have enough power to turn on the water-cooled technology tray.

- The IMM2.1 in the water-cooled technology tray is not communicating with the Chassis Management Module.

- Flashing slowly: The water-cooled technology tray is connected to power through the Lenovo NeXtScale n1200 Enclosure Type 5468 and is ready to be turned on.

- Lit continuously: The water-cooled technology tray is connected to power through the Lenovo NeXtScale n1200 Enclosure Type 5468 and is turned on.

When the water-cooled technology tray is on, pressing this button causes an orderly shutdown of the water-cooled technology tray so that it can be removed safely from the chassis. This includes shutting down the operating system (if possible) and removing power from the water-cooled technology tray.

If an operating system is running, you might have to press the button for approximately 4 seconds to initiate the shutdown.

Attention: Pressing the button for 4 seconds forces the operating system to shut down immediately. Data loss is possible. - Flashing rapidly: The LED flashes rapidly for the following

reasons:

- Locator LED

- Use this blue LED to visually locate the server among other servers. This LED is used as a presence detection as well. You can use Systems Director or IMM web interface to light this LED remotely. This LED is controlled by the IMM.

- Check log LED

- When this yellow LED is lit, it indicates that a system error has occurred. Check the Event logs for additional information.

- System error LED

- When this yellow LED is lit, it indicates that a system error has occurred. An LED on the system board is also lit to help isolate the error. This LED is controlled by the IMM.

- KVM connector

- Connect the console breakout cable

to this connector.Note: It is best practice to connect the console breakout cable to only one water-cooled technology tray at a time in each Lenovo NeXtScale n1200 Enclosure Type 5468.

- Ethernet connectors

- Use either of these connectors to connect the server to a network. When you enable shared Ethernet for IMM2.1 in the Setup utility, you can access the IMM2.1 using either the Ethernet 1 or the system-management Ethernet (default) connector. See Using the Setup utility for more information.

- Ethernet link activity/status LED

- When any of these LEDs is lit, they indicate that the server is transmitting to or receiving signals from the Ethernet LAN that is connected to the Ethernet port that corresponds to that LED.

- Management connector

- Use this connector to connect the server to a network for full systems-management information control. This connector is used only by the Integrated Management Module 2.1 (IMM2.1). A dedicated management network provides additional security by physically separating the management network traffic from the production network. You can use the Setup utility to configure the server to use a dedicated systems management network or a shared network.