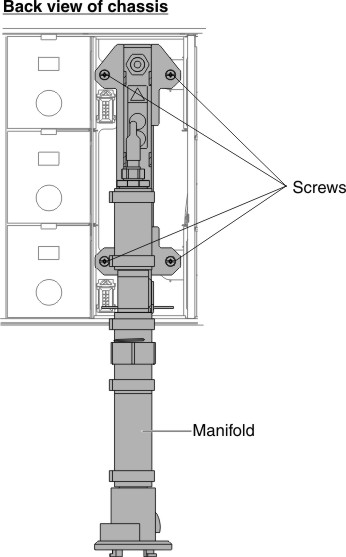

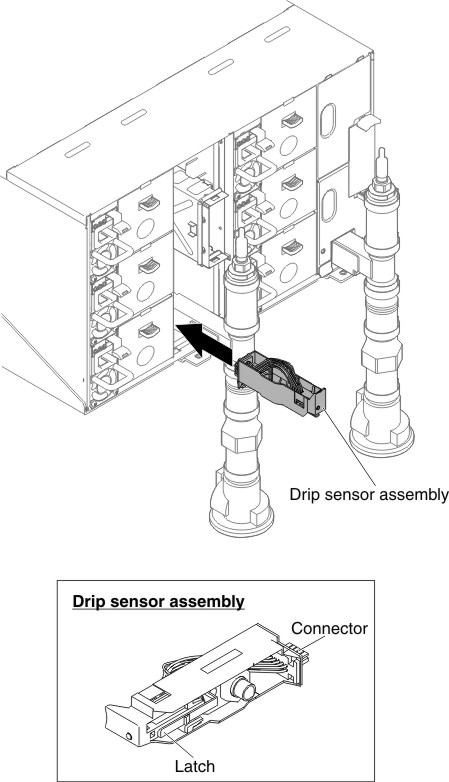

Use this information to replace the manifold.

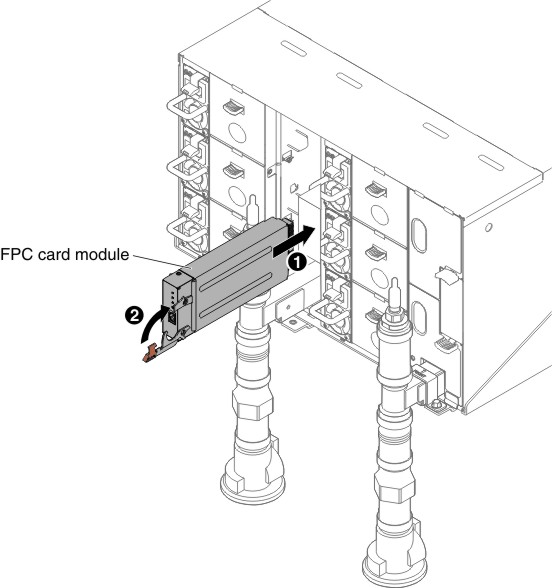

Important: Make sure the water-cooled technology tray(s) are removed from the chassis (see Removing a water-cooled technology tray from a chassis).

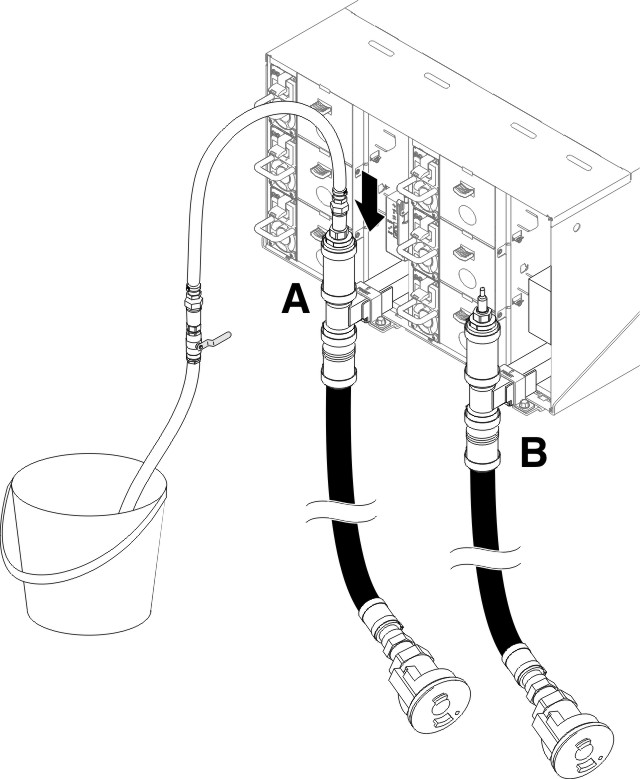

Attention: You must remove the power from the

rack cabinet and all components before you connect or disconnect the

water supply lines and drain or fill the manifold.

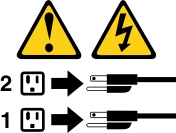

Statement

5

CAUTION:

The power control button on the device and the power

switch on the power supply do not turn off the electrical current

supplied to the device. The device also might have more than one power

cord. To remove all electrical current from the device, ensure that

all power cords are disconnected from the power source.

DWC Safety

Information, Statement 14

CAUTION:

The water might cause irritation to the skin and eyes. Avoid direct contact with the lubricant.

(C034)

Attention: Ensure proper handling procedures are followed when

working with any chemically treated water used in the compute rack

cooling system. Ensure that material safety data sheets (MSDS) and

safety information are provided by the water chemical treatment supplier

and that proper personal protective equipment (PPE) is available as

recommended by the water chemical treatment supplier. Protective gloves

and eyewear may be recommended as a precaution.

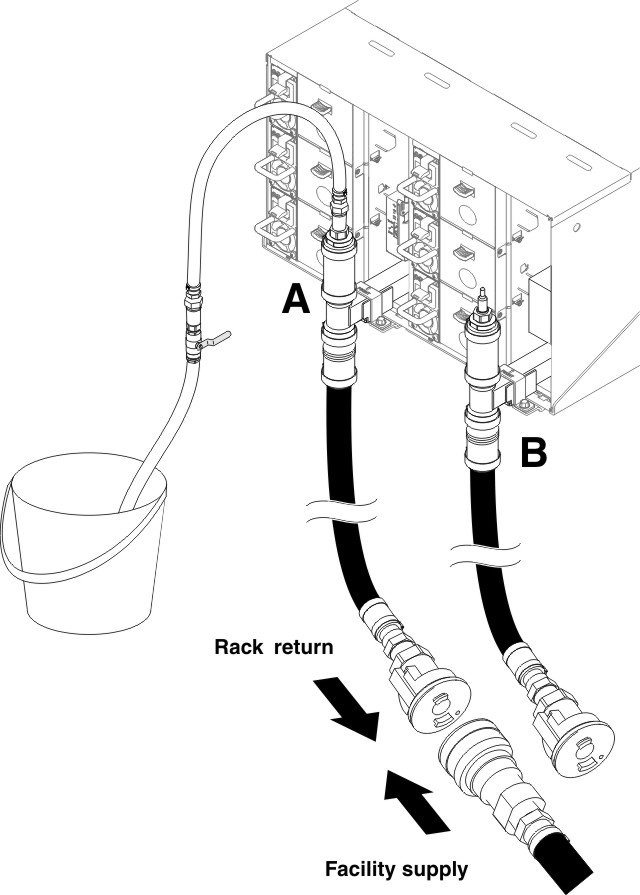

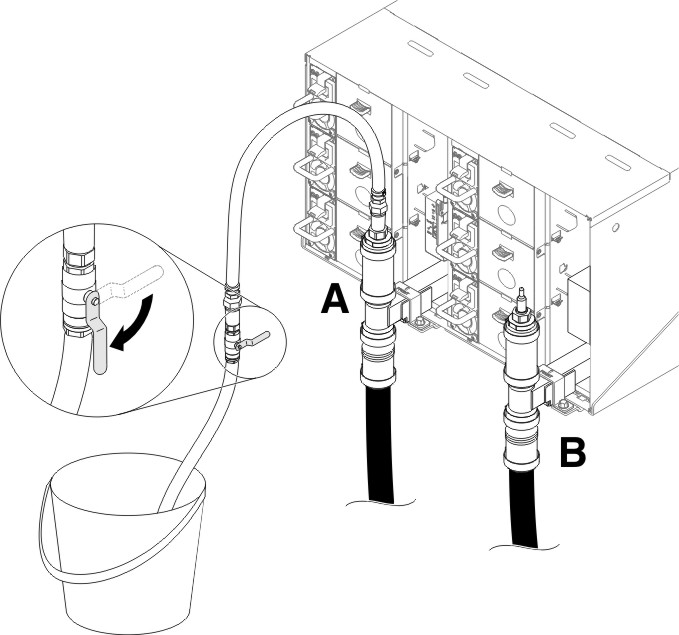

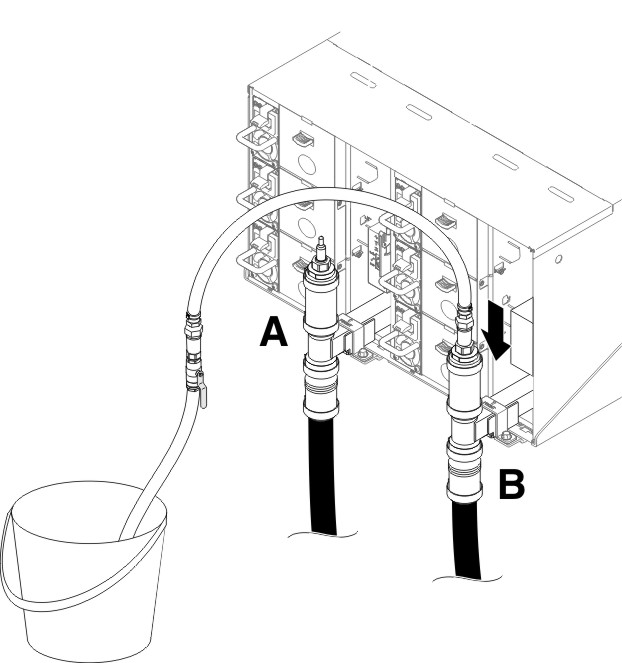

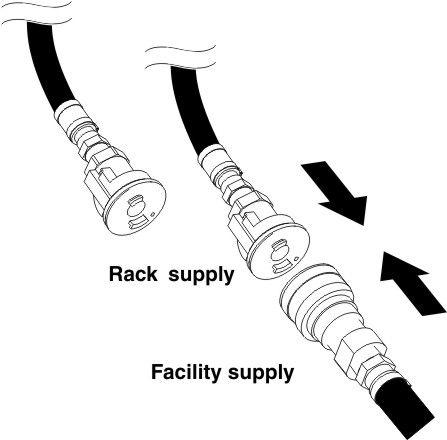

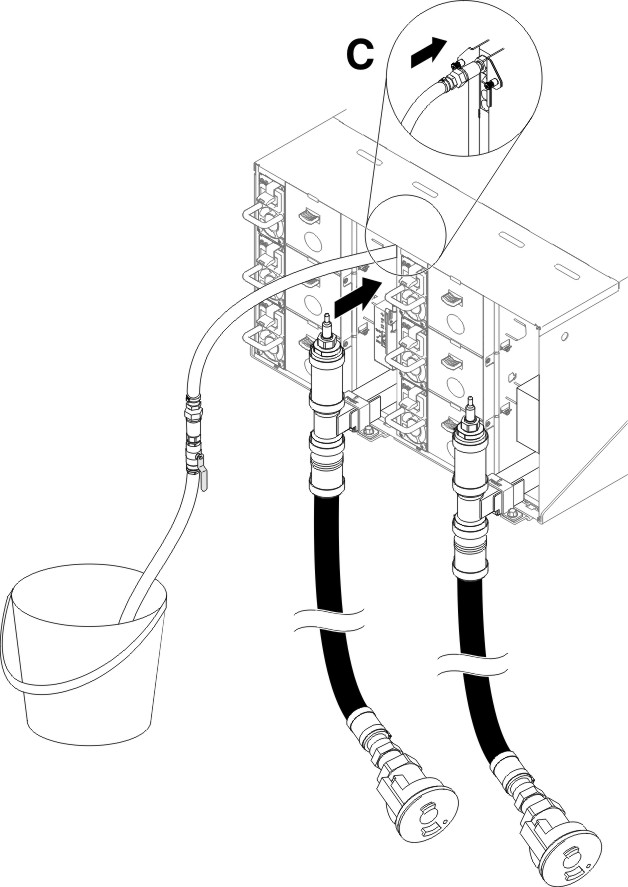

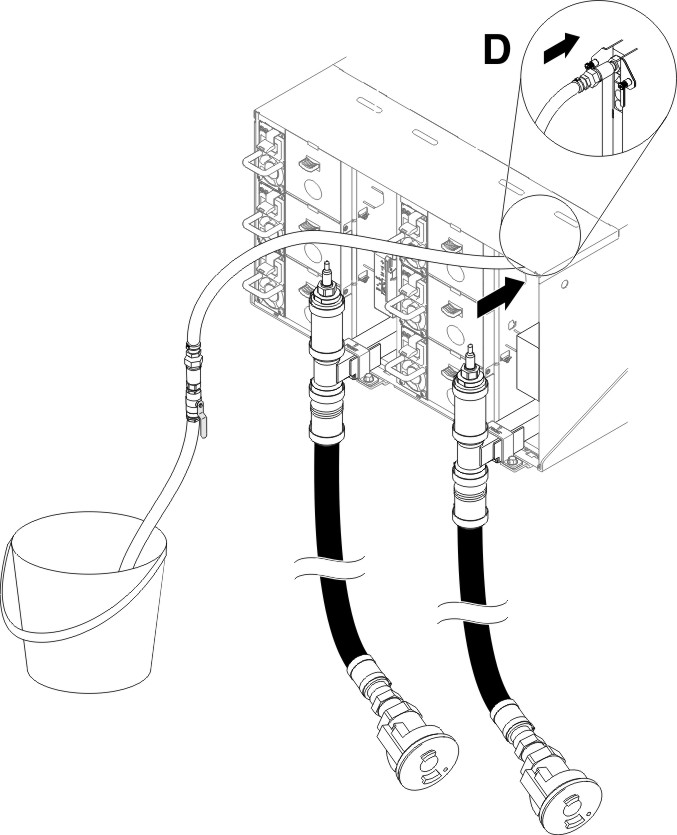

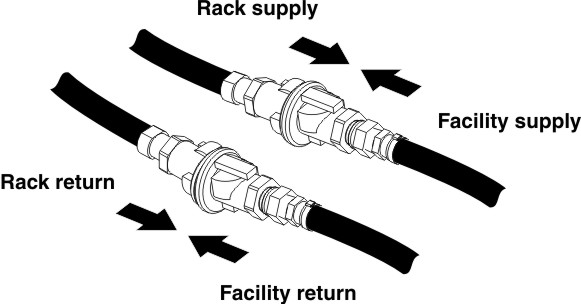

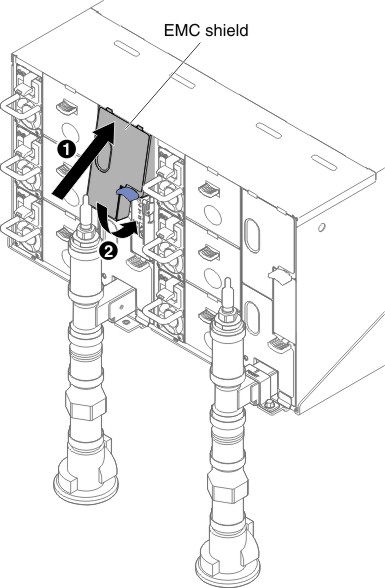

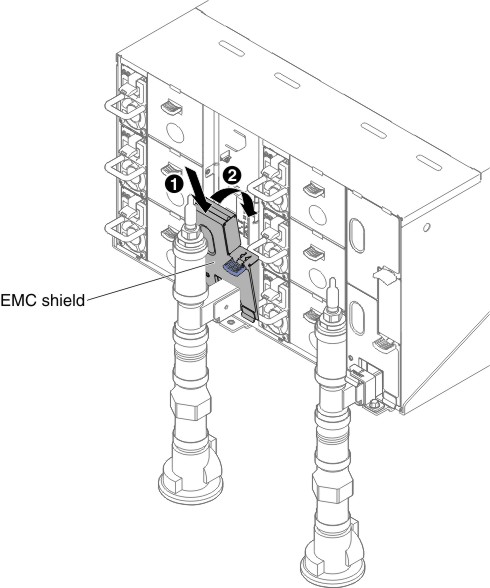

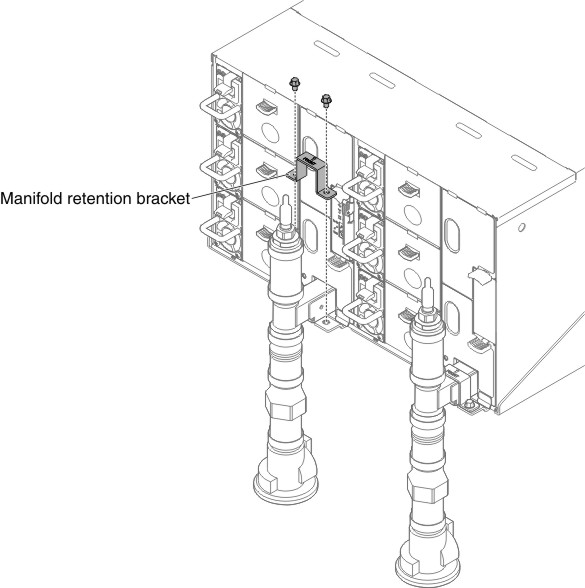

To replace the server manifold, complete the following steps.